Tesla image source / Ford image source

Tesla image source / Ford image source

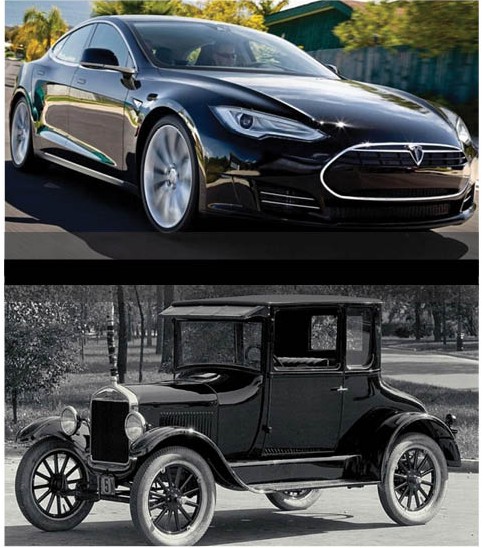

When the Ford Model T was first introduced in 1908, there were only 18,000 miles of paved road throughout the United States. Motorized vehicles were just gaining popularity,

Now, just a little over a century later, there are almost 4 million miles of paved road in our country — and despite many other options to move people around, cars are still the mode of transportation Americans choose most of all.

In late March 2016, Tesla Motors announced its Model 3. Buzz around the vehicle has rivaled that of Apple’s iPhone, with reservations for the new vehicle already numbering in the hundreds of thousands.

How can we compare the electric car taking the modern world by storm to Ford’s earliest mass-market vehicle? While it might seem like a stretch, these two vastly different vehicles actually have a lot in common. Read on to learn more.

1. They’re Produced By Companies Led By Visionaries

Henry Ford didn’t invent the car, and he didn’t invent the assembly line. But he reinvented the entire industry — and brought it into the modern era — with his Model T, popularly known as the “Tin Lizzie,” and made them affordable to the masses (including many of his factory workers).

The Henry Ford museum in Dearborn tells the story of how Ford, upon receiving a pocket watch for his 13th birthday, promptly disassembled it.

“He simply wanted to know how it worked. It was a character trait that marked the rest of Ford’s life,” according to the website. “He wanted to know how things worked and, just as important, why they didn’t work.”

Fast-forward to 2016: Elon Musk, Tesla’s CEO, is not an auto-industry tycoon. He created Zip2, a media company that sold for $300 million in 1999, and he made his first fortune as a co-founder of the online payment company now known as PayPal.

He founded SpaceX, a company bent on creating crafts for commercial space travel, and Hyperloop, a transportation technology that “would propel riders in pods through a network of low-pressure tubes at speeds reaching more than 700 mph,” according to biography.com.

He joined Tesla after leading its Series A funding round, and has since become the driving force behind its growth.

2. Tesla and Ford Democratized Advanced Technology

The Model T wasn’t the first car Henry Ford created, but it was the most accessible to American drivers.

According to the Henry Ford Heritage Association, a new Model T cost $850 when it was first released in 1908. Because of increased production efficiency and happier workers making $5 per day, the price dropped again and again: By the end of the line’s production in 1927 — just 19 years later — a new Model T was priced at $260.

Where Ford made passenger cars accessible to a larger population, Tesla is working to democratize electric cars for everyday people.

Previous Tesla models have come with a hefty price tag: A new-model Tesla Model S starts at $75,000. But just as the Ford Model T decreased in price after years of technological tweaks and manufacturing innovations, so has the price of the Tesla Model 3. Industry analysts predict the vehicles will sell for a base price of $35,000.

And demand for the cars has already skyrocketed accordingly: More than 325,000 buyers have already paid $1,000 to reserve a car, with cars expected to begin rolling off the line in late 2017.

3. Both Have Changed The Industry

The Moving Assembly Line

In ramping up production of the Model T, Henry Ford reinvented the automobile assembly line. Rather than workers moving to assemble vehicles in stages, a moving assembly line brought each stage of the building process to the workers.

According to Ford’s corporate website, “the new process revolutionized production and dropped the assembly time for a single vehicle from 12 hours to about 90 minutes.”

Eventually, a Model T was leaving the factory every 24 seconds. (For scale, Ford’s assembly lines — of much more complex vehicles, granted — now send off about 16 vehicles every 60 seconds, according to Ford’s corporate website.)

Open-Source Technology

Tesla, like any car company, patented their electric vehicle technology in its infancy. However, in June 2014, CEO Elon Musk announced Tesla would not “initiate patent lawsuits against anyone who, in good faith, wants to use our technology,” according to a blog post.

“Technology leadership is not defined by patents, which history has repeatedly shown to be small protection indeed against a determined competitor, but rather by the ability of a company to attract and motivate the world’s most talented engineers,” Musk wrote.

4. Tesla and Ford Changed The Workplace

Shortening The Work Day And Increasing Wages

We now recognize that Henry Ford’s workplace innovations for his significant contributions to the creation of the American middle class.

Henry Ford shortened his factory workers’ day from nine hours per day to eight. He also instituted “$5 Day,” which doubled workers’ daily pay and brought 10,000 applicants to Ford’s hiring office hoping to get a job.

With the invention of the modern assembly line, according to the Henry Ford Heritage Association, Ford Motor Company offered jobs for auto workers far beyond factory line workers. Positions within Ford’s operations included roles for:

- Railroad engineers and brakemen

- Coal miners

- Lumberjacks and sawmill workers

- Ship’s captains and deckhands

- Steel and glass workers

The upshot: The eight-hour day allowed Ford to create a third shift, thus increasing production; and thanks to higher pay, employee satisfaction and retention increased, and more of Ford’s employees were suddenly able to purchase the cars they were working so hard to produce.

Bringing New Skill Sets To Auto Manufacturing

The Tesla Model 3 will be produced at the company’s massive Fremont, Calif., facility. The number of jobs that will be created as a result is unknown.

But we do know that in addition to hiring workers to build the chassis and manufacture the physical components that will make up each Model 3 vehicle, Tesla is creating jobs for employees that other mainstream automobile manufacturers haven’t needed to consider.

Tesla will need more advanced programmers to write the software that operates the vehicles.

And on the horizon, it will hire many workers to manufacture the lithium-ion batteries that will power the Model 3, as well as charging stations for homes and municipalities.

That manufacturing will take place at a so-called “Giga factory” outside of Reno, Nev., a $5 billion facility. Tesla projects that the factory will need to hire 6,500 workers by the time it reaches full production capacity in 2020, according to manufacturing.net.

5. They Changed the Landscape

Ford in Detroit

According to the Gilder Lehrman Institute Of American History, the founding of Ford Motor Company in Dearborn, Mich., was the single largest contributor to Detroit becoming one of the most diverse cities in America — not to mention a bustling city of industry — at the turn of the 20th century:

“The auto magnate recruited skilled artisans from the shipyards of Scotland and England and blue-collar workers from the rural Midwest, as well as workers from Mexico and Lebanon, and African Americans from the city’s rapidly growing population of southern migrants. By 1940, Ford was one of the largest private employers of African Americans in the United States.”

NUMMI in the Bay Area

A century later and nearly 2,500 miles to the west, Tesla is reimagining the auto manufacturing facility once known as NUMMI (General Motors and Toyota’s New United Motor Manufacturing, Inc.).

NUMMI closed in 2010, after more than 25 years spent producing up to 400,000 cars per year, and Tesla snatched up the building (at the nadir of the auto industry’s recession) for far below the asking price and began retrofitting the facility for production of the electric vehicles. Today, it’s staffed with a hybrid workforce of thousands of humans and hundreds of robots named after X-Men characters.

Production of the Model 3 will test the limits (and likely prompt further innovation) of the facility’s production capabilities.

With more than a century between the creation of the Model T and moving assembly line, their impact on our modern life as drivers is clear: They made driving a way of life for the masses and paved the way for the evolution of the automobile industry.

The long-term impact of Tesla Motors and its Model 3, which is a still a glimmer in the eye of a rapidly shifting industry, is still unknown. But the eyes of the media, industry analysts and drivers all over the world are on Tesla as it takes on creating the next generation of automobiles in a shifting global landscape.

At Adecco, we have clients in every sector and every region of the country who have staff augmentation plans in place.